Photomask services

Photomasks

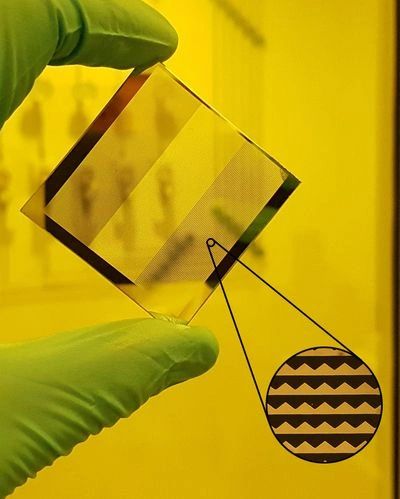

Chromium glass masks are used in microfabrication processes to engineer systems for many different applications going from electronic sensors to microfluidic devices.

They are typically fabricated using a high rate disposition sputtering system with a big deposition area. Standard photolithography and chemical etching are used and different patterns can be engraved giving a great versatility for your project. Chromium glass masks are easy to use and clean and very resistant to wear, making them an excellent choice for your microfabrication process.

Our company has photomask production capabilities offering a unique service in Latin America. We have access to high quality, high rate deposition systems combined with high resolution, fast optical lithography equipment of our own production (our own µLaser).

This allows us to offer a high quality, fast, and low cost service in the fabrication of photolithography masks for microfabrication processes.

Specs

Substrate

Material:

- Chromium over Soda lime glass

Mask size:

- We have optimized all the glass processing equipment for 50x50 mm^2 masks.

- We can do other sizes upon request.

Writing

Raster resolution: 0.8 µm (31750 DPI)

Minimum feature size: 8 µm minimum, 16 µm preferred

CAD format: Binary graphics (.bmp, .png), GDSII

- We can invert (opaque/transparent) for clear/dark field masks, or mirror the design on our software if needed, please ask when submitting the file.

- We will send you a preview for verification before manufacturing to avoid errors.

Examples

All of our writings are made with our µLaser, you can see writing demos on its webpage:

Mask blanks

Additionally, our company can provide blank chromium coated glass for your own mask fabrication.

A chrome layer is deposited using sputtering deposition on a glass substrate.

- We usually manufacture 50x50 mm^2 chromed soda lime blanks and 25x75 mm^2 chromed microscope slides.

- We can also produce other sizes upon customer request.